September rears its head!

Cups and Coasters

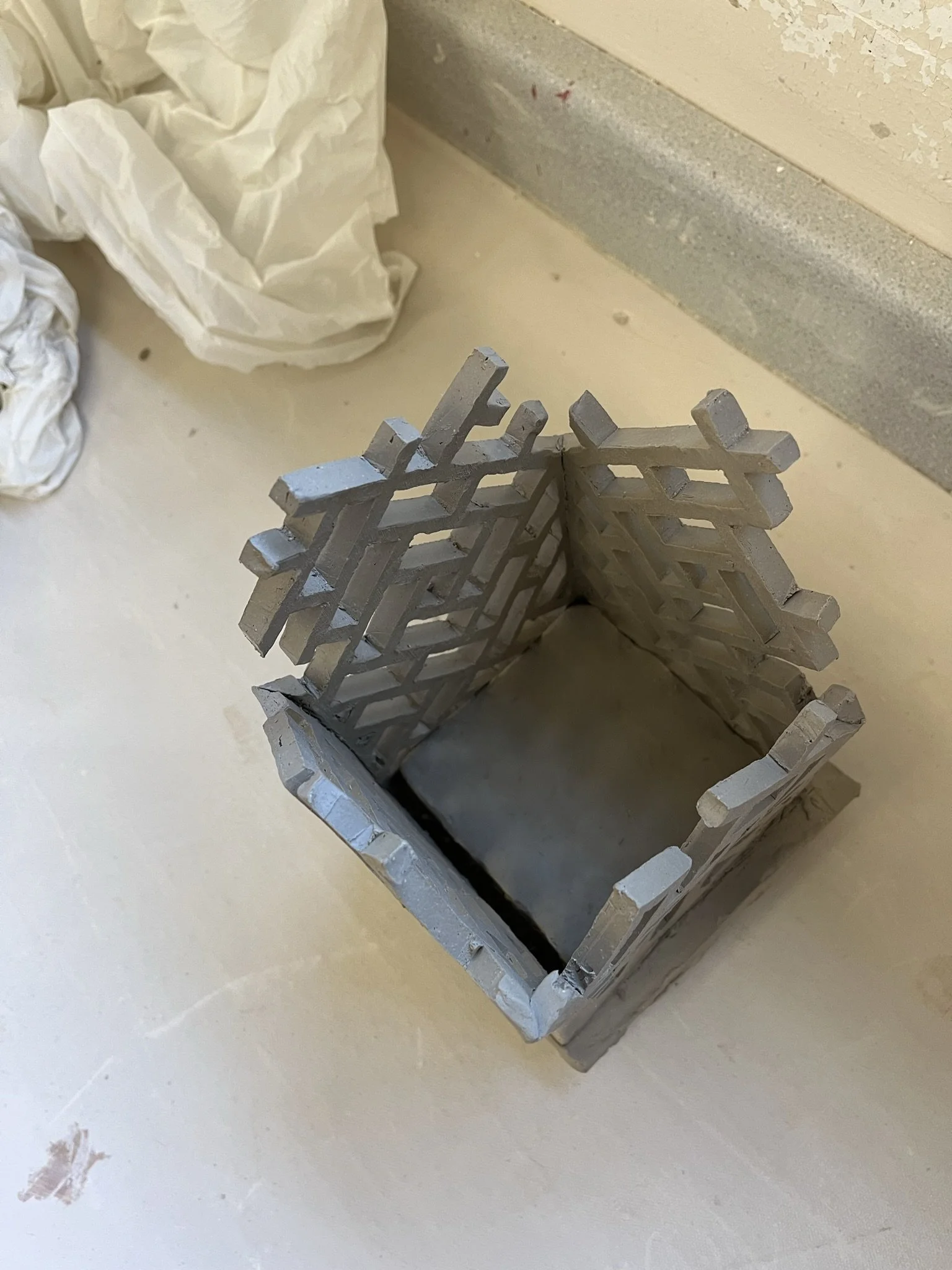

Lantern Assembly

Over the past week, I compiled a list of goals to work on throughout the fall semester. I made a public short-hand list to the right for all of you. This way, I can keep myself publicly accountable and to better contextualize the journey I am going to be taking over the next couple of months.

Commitments to Myself for 2022

Exploration of the blinding light series through the alteration of forms and 3D modeling

Practicing the teapot/coffee pot form and their associated wares

Studying the soda fire process through the use of flashing slips and firing schedules

This past week was filled with ups, downs, and a lot of lessons. First, I figured out a new pot form! Imagine a teapot that can also act as pitcher…well that’s just impractical. Lesson one:

Not only does the spout need to be at level or above the lid, the opening needs to be at a pretty steep angle away from the body of the pot. Somewhere between negative 45 and 90 degrees gives enough leeway to prevent your teapot turning into a pitcher.

So, with that learned, I culled some pots and continued practicing the teapot. Next, I had to relearn a lesson that has been preached to me over and over again, but not in a pottery class. Lesson two:

Measure twice and cut once. Take care in preparation or your end results may be unsatisfactory.

I always heard this in my sculpture and carpentry classes and it is very applicable to slab work. I regrettably did not check all my measurements when assembling my lantern and it left me with both a metaphorical and physical gap. Aaahhh, okay, deep breaths, we’re going to try that again later. But first we have to fix the sprayer.

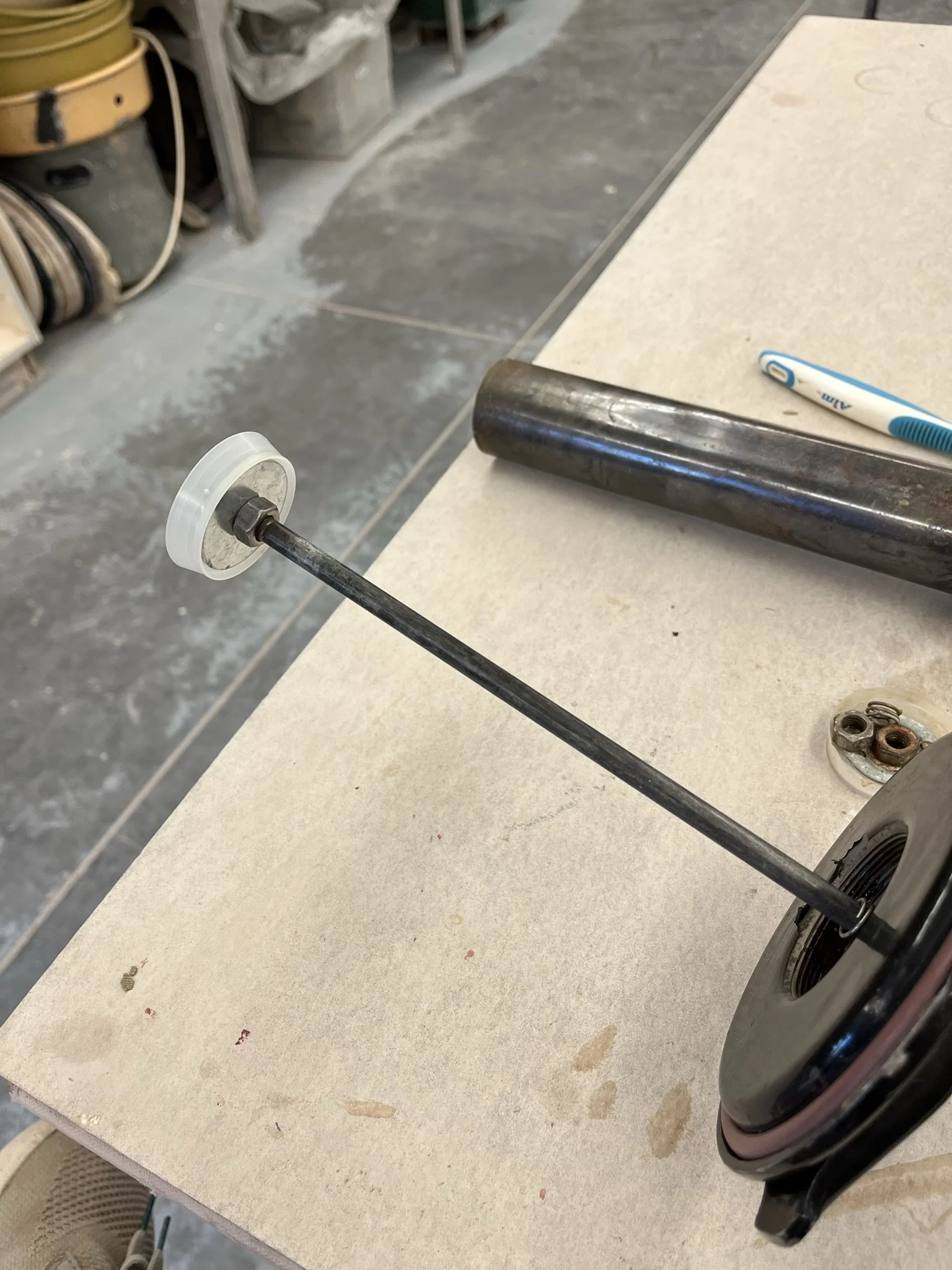

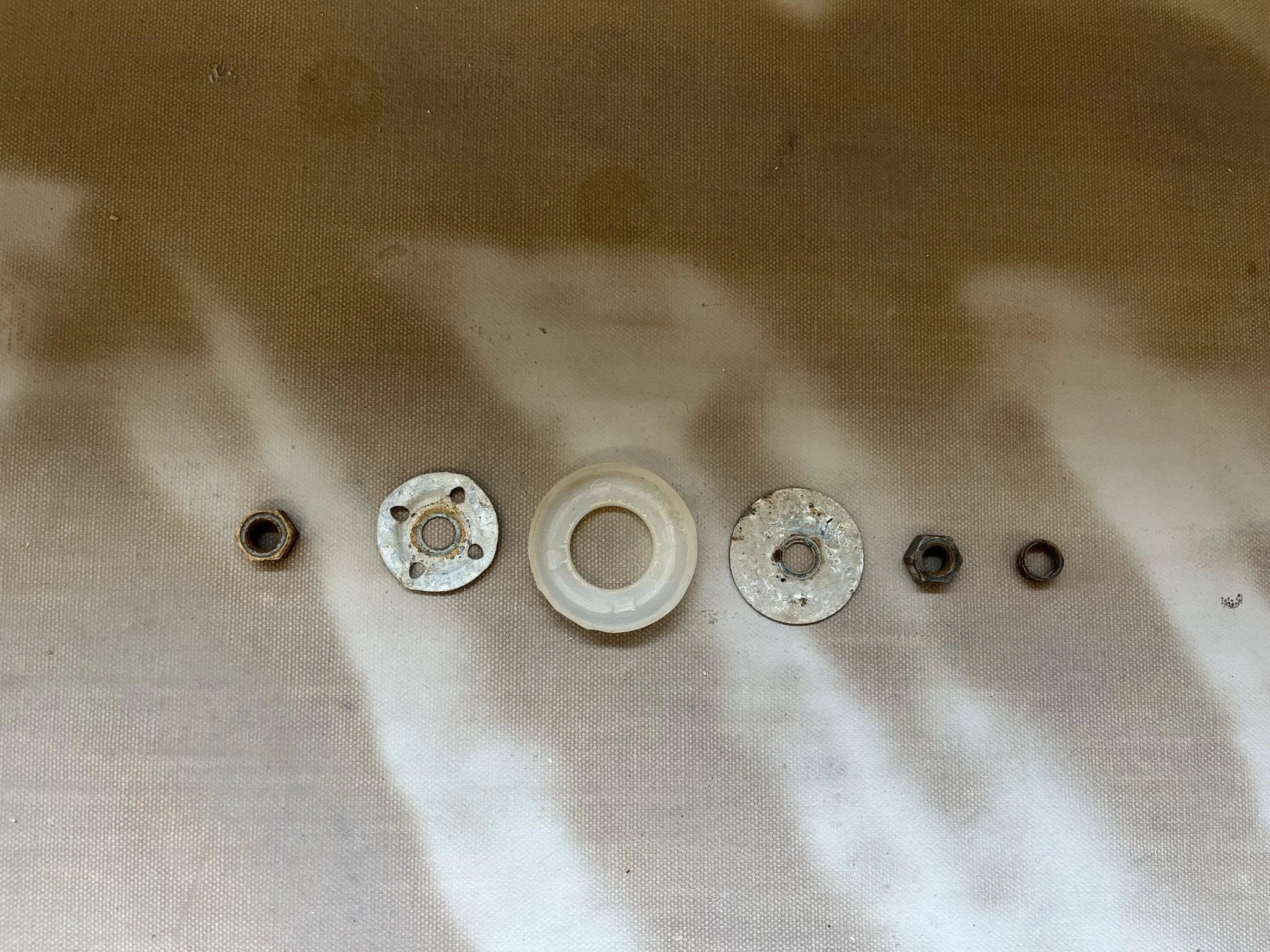

The pressurized sprayer that is used for the soda firing process broke during the last firing. The pressurizing tube wasn’t building pressure. After many attempts, clamps, and a bench vice-I was finally able to remove the outer casing tube to reveal the plastic plunger inside. And…Oh boy, it hadn’t been attended too in quite some time. Lesson three:

A more practical and less metaphysical lesson on how to fix and perform maintenance on the soda sprayer and pressurizing plunge.

After a quick cleaning, to prevent sticking again, and replacing all the parts, the sprayer flawlessly passes water and at an even greater rate. Woohoo!!